- 简体中文

- English

- 繁体中文

- Русский

- 日本語

- 한국 사람

- Français

- Deutsch

- हिंदी

- Português

- Español

- بالعربية

- Corsu

- guarani

- kinyarwanda

- Hausa

- Norge

- Nederlands

- Yoruba

- गोंगेन हें नांव

- Latina

- नेपालीName

- čeština

- ʻŌlelo Hawaiʻi

- ჯორჯიანიName

- فارسی

- भोजपुरी

- беларускі

- Kiswahili

- ÍslandName

- ייַדיש

- tur

- Gaeilge

- ગુજરાતી

- Slovenská

- היברית

- ಕನ್ನಡ್Name

- Magyar

- தாமில்

- بالعربية

- বাংলা

- Azərbaycan

- lifiava

- IndonesiaName

- dansk

- Shona

- Bamanankan

- Lietuva

- Tiếng Việt

- Malti

- Türkmençe

- অসমীয়া

- català

- සිංගාපුර්

- Suomalainen

- Кыргыз тили

- Eʋegbe

- Hrvatski

- a n:n

- Quechua

- bosanski

- Maori

Quality plays a crucial role in the electronic component supply chain. It is a standard of excellence measured against the requirements associated with the product. Of all product attributes, electronic components are required to meet the highest quality standards. If not, the risk of poor product performance, as small as a coffee maker or a pacemaker, will be multiplied.

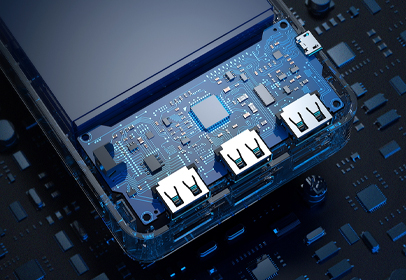

Manufacturing a semiconductor component involves hundreds of steps that can take a total of three months, and sometimes more than three months. Original component manufacturers (OCMs) must strictly control everything from air quality and temperature to the uniforms of the technicians who make the semiconductors. Even the transportation of semiconductors must use special containers and packaging, otherwise the performance efficiency of the chip will be reduced, or it will lose its function completely.

A piece of semiconductor has completed its journey from design to mass production, but its Odyssey into eventual use is just beginning. For many original equipment manufacturers (Oems), contract manufacturers (CM), original design manufacturers (ODMs), and even more, product quality is not guaranteed until the last step.

Why not? Because counterfeit components exist. Since the start of the chip shortage in 2020-2022, the detection rate of products has increased dramatically. Chip scarcity has fueled long lead times, and desperate demand has left many manufacturers struggling. Manufacturers passively wait for inventory and buy chips from contract suppliers as soon as it becomes available. As a result, long lead times have forced these manufacturers to halt production or reduce production to stay afloat. Their second option is to buy chips from unknown sources, often from merchants who claim to have inventory on hand.

Manufacturers who choose the second option are likely to receive a fake order.

In an article in the Wall Street Journal, he pointed out, "What's worse than a chip shortage? That's buying a fake." In this 2021 article, author Stephanie Yang details how desperation over a chip shortage is forcing some Oems to look to platforms or distributors they wouldn't normally embrace. The article specifically described a scenario in which BotFactory, a New York-based 3D printer manufacturer, after weeks of chip shortages and lost sales, resorted to buying semiconductors from Alibaba to maintain inventory.

The shipment they received was shipped in plastic wrap, not in the anti-static packaging used to transport components, not to mention that the chips were not usable. But it's a remedy BotFactory and many other Oems have had to take. Due to the chip shortage, global sales will lose more than $500 billion between 2020 and 2022. But fakes are not just a danger during shortages.

The Semiconductor Industry Association estimates that counterfeit electronics cost the semiconductor industry $7.5 billion a year. Even an estimated 15 percent of spare or replacement semiconductor devices purchased in the United States are counterfeit. This is a statistic obtained by the SIA at a SASC hearing in 2011. The previous year, in 2010, VisionTech Components administrator Stephanie McCloskey was sentenced for facilitating the sale of thousands of counterfeit components between 2007 and 2009. McCloskey and other associates consigned some of these circuits to major U.S. defense contractors. McCloskey v. United States of America was the first federal case involving trafficking in counterfeit integrated circuits. But the counterfeiters have not stopped.

In 2012, an investigation by the Senate Armed Services Committee found that more than 1 million counterfeit electronic components were used in equipment designed for the U.S. Air Force, Navy and Special operations. It has long been recognized that fakes lurk into highly sophisticated supply chains, but the 2012 report shows that the risk of counterfeiting has not diminished. The shortage of chips has instead encouraged counterfeiters to produce more accurate products.

In February 2022, the nuclear power plant found counterfeit parts in its supply chain. Look back at BotFactory's ill-gotten gains in the spring of 2021. Thus, the true extent of the damage caused by counterfeit goods during the chip shortage may take several more years to fully emerge. The shortage of automotive chips has not gone away, which provides a good opportunity for counterfeiters to take advantage of Oems or other manufacturers in need of chips.

In the distribution of electronic components, quality management is critical because of counterfeits and the risks they pose to the semiconductor supply chain.

What makes a QMS and why is it important to continuously improve it?

Not all quality management systems (QMS) are effective. Counterfeit goods and other defective goods can still enter the supply chain through improperly designed and maintained QMS. Once counterfeits successfully enter the supply chain, or worse, directly into the product, it's not just the economy that suffers. There are at least seven different sources of counterfeit components on the market: recycled, rebranded, overproduced, substandard, cloned, counterfeit, and tampered with. Each one is dangerous.

The University of Florida study found that counterfeit and shoddy products pose security and reliability risks to critical systems or infrastructure. By helping organized criminal groups compromise the security and integrity of modern societies, this behavior reduces the incentive to develop new products and related ideas, which ultimately affects innovation, economies, and jobs worldwide. Therefore, counterfeit detection is an important part of the quality management system, and specific detection can quickly identify fakes and even damaged devices.

There are ways to quickly determine if an electronic components distributor has a proper quality management system in place. The first step is to take the time to find out if the distributor has the relevant certifications. Electronic component distributors shall have ISO 9001:2015 certification and be able to produce certification documents issued by the relevant regulatory authority. ISO 9001 certification is only issued by a third party authorized by the American Electrostatic Discharge Association (ESDA). ESDA has a full list of authorized agencies on its website to confirm.

What is ISO 9001? It is defined as an international standard that specifies the requirements for a quality management system. The standard was first published in 1987 by the International Organization for Standardization (ISO), a global body made up of national standards bodies in more than 160 countries. ISO 9001 is the only standard in the family that allows organizations to obtain certification after demonstrating their ability to consistently deliver products and services that meet customer and regulatory requirements. ISO 9001 certification can be held by any organization, regardless of its size and industry. Certified companies report that ISO standards help them organize processes, increase process efficiency, and continuously improve.

Related information

-

Phone

400-666-5385 -

Wechat